Elastollan

Thermoplastic Polyurethane

Elastollan thermoplastic polyurethane (TPU) is a thermoplastic elastomer (TPE), a material that bridges the gap between rubber and thermoplastics. TPU excels in terms of abrasion resistance, cut/ tear resistance, elastic memory, chemical resistance, and hydrolytic stability. Aerospace grades are formulated to comply with the industry’s FST standards. Typical applications are found in the cabin interior such as armrest surfaces, protective housings, soft touch applications and innovative seat cushions.

Chemistry-Structure-Property Relationships

|

TPU is a segmented block copolymer with alternating rigid and flexible segments. These segments are formed by the reaction of aromatic or aliphatic diisocyanates with linear polyesterols of adipic acid, glycol and butanediol and/or with polytetrahydrofurane, a polyetherol. The properties of resulting products depend on phase separation during the polyaddition reaction. A flexible phase is essentially made up by the polyol soft segments which effect low temperature properties, resistance to solvents and weatherability as well as extent and morphology of hard segment aggregation. The hard segments, consisting of the diisocyanate and butanediol units, form a rigid, crystallizable phase. They determine thermo-mechanical properties such as hardness and upper service temperature.

It is this combination of flexible, elastic segments with a high extensibility and low glass transition temperature, on the one hand, and rigid crystallising segments with a high melting point, on the other, that gives the material its elastomeric nature.

|

Wide property spectrum

|

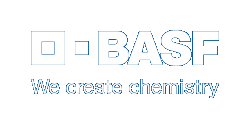

The TPU structure can be varied by using building blocks of different chemistries and/or by altering the ratio between the hard and soft segments. As a result, physical and mechanical properties such as hardness, strength, rigidity, elongation and

low-temperature flexibility can be adjusted over a broad range. Elastollan TPU grades are available with hardnesses from 35 Shore A to 74 Shore D. |

Most Elastollan TPU grades are based on aromatic chemistries which endows resins with easy processibility and property

matrices that cater to the majority of applications. Aliphatic isocyanates are used in specialty grades providing outstanding

color stability, transparency, and weatherability. A distinction is drawn between polyether and polyester polyurethane as a

function of the polyols employed. In conjunction with polyester-polyols, TPU with high toughness, good oil and solvent

resistance, weatherability, abrasion resistance and temperature resistance are obtained. Polyether-polyol-based TPU exhibit

excellent hydrolytic stability, resistance to weak acids & bases, and fungus & microbial resistance.

matrices that cater to the majority of applications. Aliphatic isocyanates are used in specialty grades providing outstanding

color stability, transparency, and weatherability. A distinction is drawn between polyether and polyester polyurethane as a

function of the polyols employed. In conjunction with polyester-polyols, TPU with high toughness, good oil and solvent

resistance, weatherability, abrasion resistance and temperature resistance are obtained. Polyether-polyol-based TPU exhibit

excellent hydrolytic stability, resistance to weak acids & bases, and fungus & microbial resistance.

|

Polyester-based TPU

|

Polyether-based TPU

|

Aliphatic TPU

|

Aerospace applications

|

Elastollan TPU is used in various aircraft interior applications. A variety of grades with hardnesses ranging from 70 Shore A to 54 Shore D are particularly suitable on account of their mechanical and physical properties. Flame retardance can be adjusted to comply with the different requirements in 14 CFR, part 25. The most notable aerospace applications include protective TV housings, armrest surfaces, innovative light-weight seat cushions, aircraft wire & cable jacketing, interlayer material for window glazings, MSA masks and puncture resistant life vests.

|

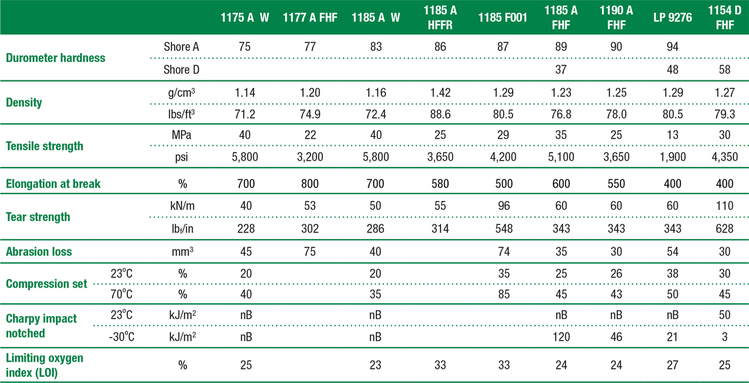

Physical and mechanical properties

|

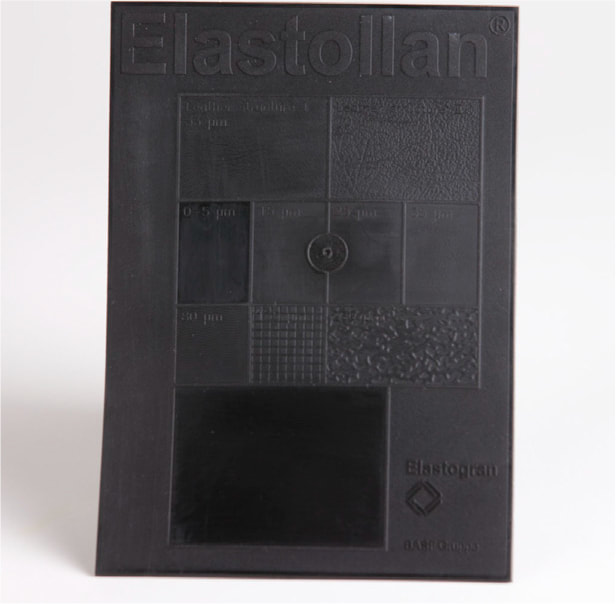

The product range of Elastollan TPU used in aerospace applications is predominantly polyether-based grades, all featuring inherent microbial & fungal resistance, excellent hydrolytic stability, and low temperature flexibility. The service temperature range spans from -54 to 125°C (-65 to 260°F). All properties listed are bulk properties. Lower density Elastollan TPUs are accessible through foaming technology. |

Processing

|

Flame retardance and regulatory compliance

BASF is the technology leader in the field of flame retardant TPU. Different FR additive packages based on proprietary halogenated and non-halogenated flame retardants are available providing the FR TPU formulations with excellent fire behavior, low smoke densities, low smoke toxicities and high limiting oxygen index (LOI) values. Accordingly, the FST properties of parts made from Elastollan TPU can be tailored to meet the specific requirements set forth in 14 CFR, part 25, depending on the target application.

|