Solyfast

UV-Activated Organotin-free Metal Catalyst

BASF flexible foams (molded flexible foams and flexible integral skin foams) have been a favorite material for armrests, headrests, and seat cushioning because they are lightweight, durable, and moldable to almost any shape, size, and level of firmness. A variety of density and hardness combinations can provide an impressive strength-to-weight ratio and excellent resistance to chemicals and fluids.

Features

|

Reduce energy consumption

|

Increased throughput

|

Reduce Cost

|

Improved Environmental Benefits

|

|

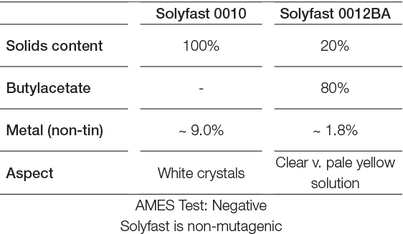

Supply forms and properties

|

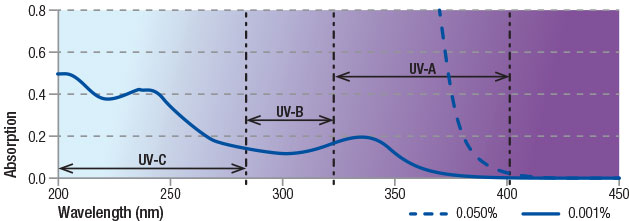

UV-Absorption spectrum of Solyfast

Solyfast 0010 can be photoactivated. The spectra shown in the graph above shows at what wavelength the photolatent catalyst absorb (and as a result triggered) by light. Solyfast 0010 is a colorless material, but it can absorb light strongly in the UV-B and UV-A spectral regions. This means that common light sources (i.e., mercury and/or metal halide lamps) can readily photo-excite the Solyfast 0010.

|

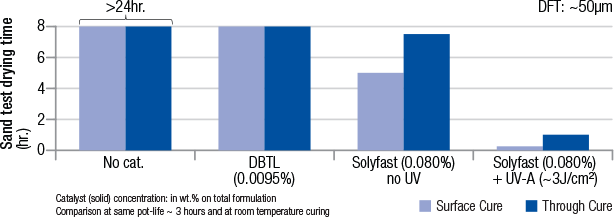

Solyfast 0010 catalytic activity

Benchmark in model 2L-PUR Clear Coat

|

A dramatic cure time reduction is seen once the resin containing Solyfast 0010 is exposed to UV-A light. Without any catalyst the 2K PUR resin has a cure time of several hours. With a standard tin catalyst (or with unexposed Solyfast 0010) the open time is > 4 hours. With a short UV- light exposure the curing time of the resin containing Solyfast 0010 is dramatically reduced to 1 hour or less. This result is critical, since it shows that light can trigger the Solyfast to speed up the cure, which is also done at room temperature. Solyfast 0010 allows faster through-put at lower temperatures.

|

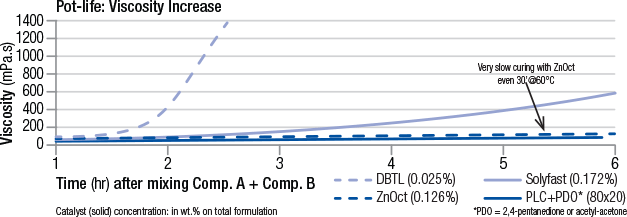

Solyfast 0010 and PotLife

Example in one model 2K-PUR Clear

|

A long sought after ability for processing 2K PUR resins is to have long open times (effective pot-life or working time) and fast cure kinetics. As shown above, different catalysts can affect the viscosity build up in the 2K PUR resin. A faster increase in viscosity equates out to shorter pot-life. A slow increase in viscosity is seen with Solyfast 0010, compared to the common thermal catalysts (ZnOct or DBTL). This means better working times. When cure is needed, then UV light can trigger quick cure times.

|

Conclusions