Ultrason

All Thermoplastic Panel (ATP)

|

BASF’s Ultrason all thermoplastic panel is composed of Ultrason reinforced thermoplastic laminate (RTL) facings with a Divinycell F foamed Ultrason core. The ATP is a recyclable alternative to honeycomb cored panels with savings along the value chain.

Benefits

|

|

Overview

The ATP has a smooth finish and high surface quality that eliminates the labor intensive sweep and sand process. Along with manufacturing savings, the ATP exceeds FST and OSU requirements making it a drop-in replacement for aerospace industry standard panels.

|

Manufacturing benefits

Interior applications

Configuration details

|

|

Ultrason reinforced thermoplastic laminate

BASF’s proprietary Ultratect technology allows the production of a polyethersulfone-based (PESU), recyclable foamed core material, made from BASF’s Ultrason E thermoplastic resin. It combines light weight characteristics with excellent mechanical properties. Typical of Ultrason, it also features low water absorption, resistance to high temperature and chemicals, excellent heat ageing behavior as well as inherent flame retardance. Divinycell F core materials were specifically developed for aircraft interior requirements. It is commercially available from the Diab Group.

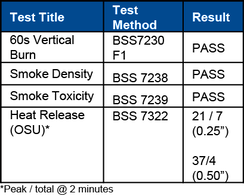

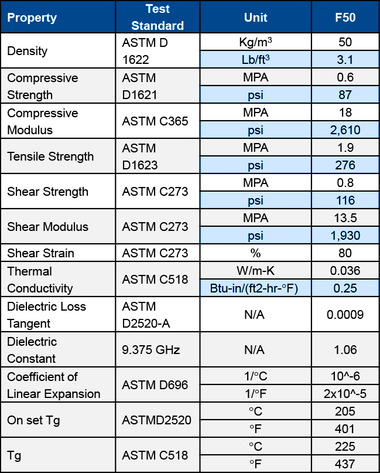

Table 2. Divinycell F50 properties

|

Table 3. Divinycell F50 results

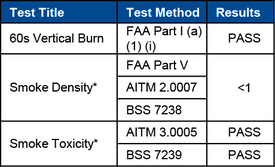

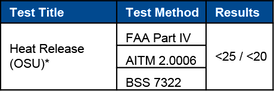

Table 4. Divinycell OSU results

Reinforced thermoplastic laminate facings

Reinforced thermoplastic laminates based on Ultrason E or P typically comprise one or more layers of glass or carbonbased fabrics. These thermoplastic prepregs are alternatives to the classical thermoset prepregs such as those based on phenolic or epoxy resin. Thermoplastic prepregs offer advantages in handling and logistics (no refrigeration required), manufacturability (significantly less surface finishing, e.g., sanding), and sustainability (recyclability), offering potential to reduce cost or providing ecological benefits.

|