Ultrason

Reinforced Thermoplastic Laminate (RTL)

|

BASF’s Ultrason Reinforced Thermoplastic Laminates (RTL) are FST and OSU compliant, offering time and labor savings as well as weight cost reductions over traditional thermoset and thermoplastic laminates.

|

|

Overview

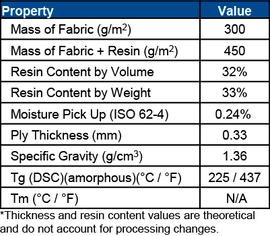

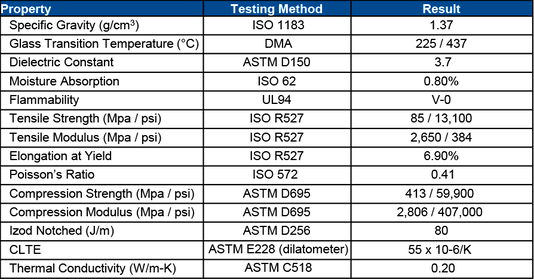

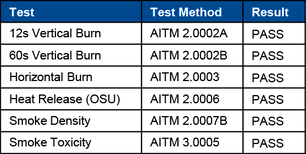

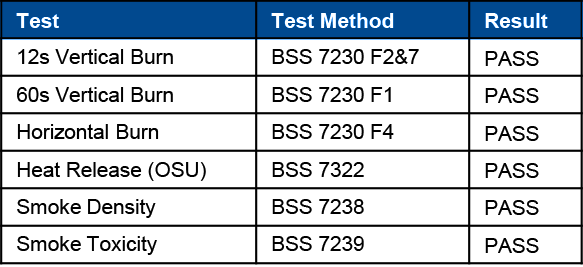

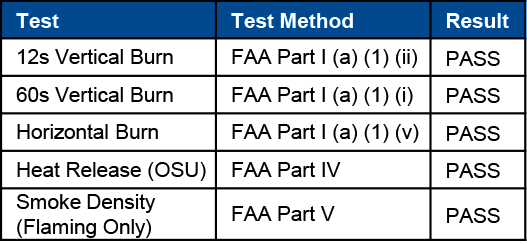

Ultrason RTL utilizes Ultrason E (polyethersulfone) resin to achieve a consistent resin-to-glass ratio ensuring FAA, Airbus, and Boeing FST requirements are met. The RTL is offered in one- and two-ply configurations with the core and resin layers composed of 7781 E glass fabric and Ultrason E 2010, respectively. Each product is manufactured in role form (2’ x 100’), which minimizes scrap and reduces processing time compared to thermosets. This manufacturing process also results in a high surface quality RTL that reduces the need for sweep and sand processing when used as a facing material in composite panels. The versatility and performance of BASF’s RTLs are provided in Tables 1 through 5.

|

Potential applications

|