Ultrason

Semi-finished Products

By virtue of their thermo-mechanical characteristics and favorable fire, smoke, and toxicity (FST) behavior, Ultrason E polyethersulfone and Ultrason P polyphenylsulfone are particularly suitable for aircraft applications. Unreinforced and reinforced grades can be processed into sheets, laminates, and tapes which can be used directly or further converted by thermoforming or compression molding. Applications range from decorative to seating and structural in cabin interiors.

|

Features

|

Reinforced grades

|

|

Unfilled grades

|

Ultrason polysulfone shapes

|

|

Unreinforced and reinforced grades

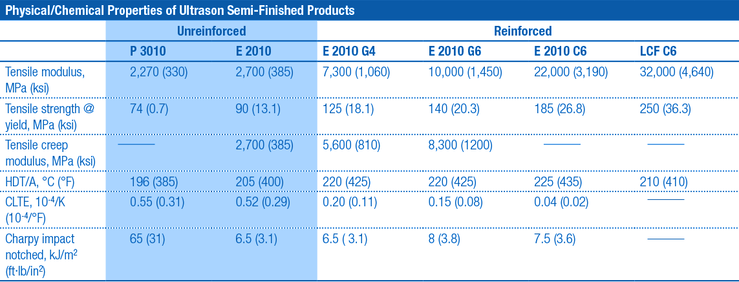

Ultrason polysulfones have a set of unique materials properties such as high heat deflection temperatures, low thermal expansion coefficients, resistance to chemicals and high temperatures, inherent flame retardance and attractive mechanical properties.

Typically, all of these properties are further improved by fiber reinforcement, in particular, rigidity, tensile strength and creep. SFT composites based on glass or carbon fiber show substantial increases in stiffness, tensile strength, creep resistance and dimensional stability. LFT composites such as the carbon-based Ultrason LCF C6 close the performance gap between SFT composites and their metal counterparts.

|

Unfilled sheet

Unfilled Ultrason polysulfones can be used to engineer large cabin parts and surfaces with thicknesses ranging from 0.5 to 5 mm (0.02 to 0.2 in.) which are inherently delamination resistant. Due to the fact that no flame retardant has to be added to the inherently fire resistant material, transparent, or translucent parts are possible. The resins’ easy colorability further increases the number of design options. For example, applications for transparent sheet material include ceiling elements, partitions, stairways, light covers, galley doors, and privacy screens. While Ultrason E polyethersulfones exhibit higher rigidity and heat distortion temperatures, Ultrason P polyphenylsulfone offers a combination of good stiffness and exceptional toughness.

|

|

Reinforced shapes

Shapes made from reinforced Ultrason polysulfones can be used as structural materials in areas of high wear in which parts of very high rigidity and impact resistance are required. Polysulfone-based SFT composites can substitute for thermosets over which they have the advantage of easier and faster processibility as well as recyclability. Processing also is more economical due to lower tooling costs. Polysulfonebased LFT composites can replace metal over which they have a significant weight advantage.

Ultrason resin can be used as a binder to manufacture LFTbased RTL. Applications are typically found as structural components in the aircraft interior.

|

Regulatory compliance

Ultrason polysulfones meet the strict requirements of the aerospace industry design options. Applications for test panels made from Ultrason P 3010 are compliant with the heat release requirements as defined in JAR/FAR 25, App. F, Part IV & AITM 2.0006. Ultrason E 2010 passes the criteria of the BSS 7230 F2 flammability test. Details are available upon request.