UNO

|

Heat Reflective Coatings

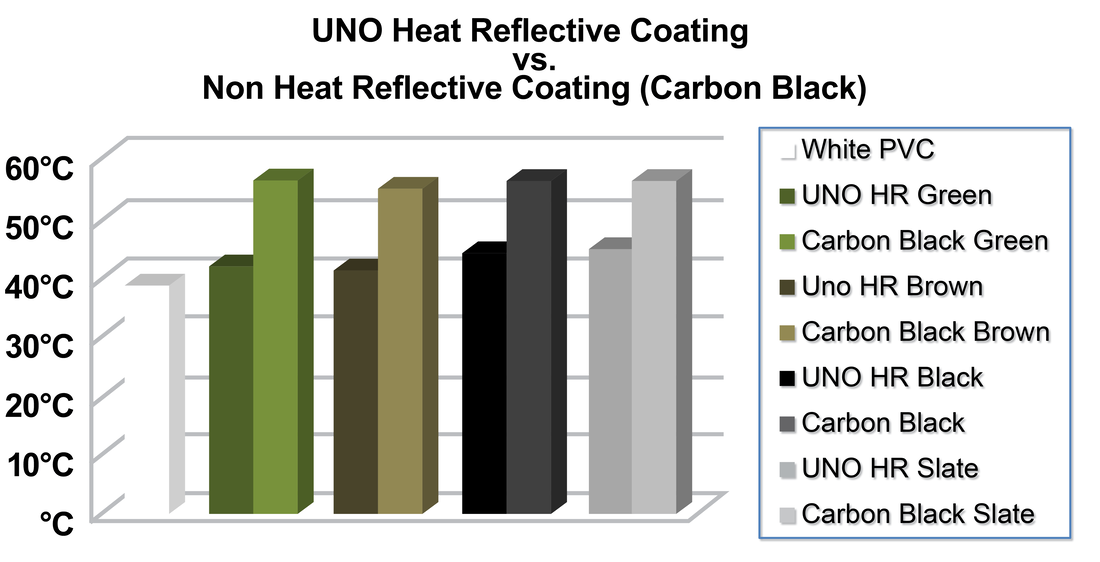

All dark surfaces exposed to sunlight heat up strongly, while light surfaces remain distinctly cooler. This is because dark surfaces absorb incident sunlight and convert it into heat, while light surfaces reflect more of the incoming energy. UNO Heat Reflective Coatings use a special reflective pigment technology to reduce heat absorption in dark colours.

|

UNO Heat Reflective Coatings Features

- Increased surface reflectance

- Reduced surface heat build-up

- Longer lifetimes for coatings through reduced temperature strain

- CC403/UNO HD meets all AAMA613 and AAMA2604 test requirements for chemical, corrosion and abrasion resistance.

|

AAMA 613/AAMA 2604 Test Results

BASF UNO CC403 passes all the following tests:

|

Heat Build Up of Colours Versus Carbon Black ASTM D4803

UNO Mixing

UNO, when mixed with gloss reducing additive, can produce gloss levels from flat(10 gloss units @ 60˚) to full gloss.

|

Color chips in this presentation display samples of color only and are not intended for use as standards.

Contact your BASF Representative for more color options.