UV Absorber Technology

Tinuvin® CarboProtect®

|

Tinuvin CarboProtect is a red-shifted UV-absorber designed for solvent-based clear or semi-transparent coatings over carbon fiber reinforced materials (CFRM) where fibers are embedded in an epoxy matrix or other UV-sensitive substrates. It provides unmatched blocking from destructive UV radiation and protects the composite materials.

Performance requirements of aerospace coatings

Aerospace coatings must perform in demanding environmental conditions, protect the substrates underneath and provide a beautiful appearance, all at increasingly demanding durability requirements and at coating weights as low as possible. BASF’s Tinuvin CarboProtect advanced UV absorber blocks destructive UV radiation and provides advanced substrates, such as CFRM with protection unmatched by conventional UV absorbers. With this novel technology, it is possible to engineer thinner coatings with increased durability and a maximum in photooxidative stability without sacrificing optical quality of the aircraft coatings. Thinner coatings cut down weight and require less drying time, thus reducing fuel consumption and maintenance costs. Furthermore, CFRM substrates are better protected even with pigmentfree coatings, allowing the carbon fiber weave to be displayed and utilized as a design element, for example, in parts in the cabin interior

|

|

Features and benefits

|

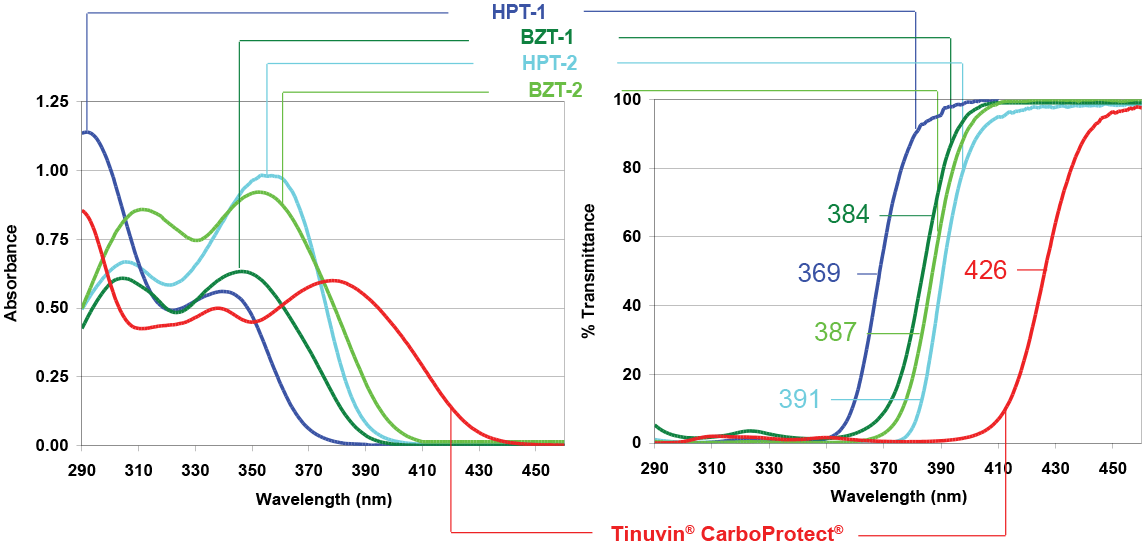

Protection of epoxy-based composites

Composites based on aromatic polymers, e.g. carbon fibers in a thermoset aromatic epoxy matrix are inherently light sensitive. Fundamental studies reveal that critical wavelengths comprise both the UV range (280–380 nm) and the visual range (400–420 nm). No traditional UV absorber technology protects as far out as 420 nm to prevent degradation of epoxy-based CFRM. Tinuvin CarboProtect was designed to do just that: based on a very red-shifted, benzotriazole-based technology, its spectral coverage comprises UV-A and UV-B as well as the near visible wavelength range, with a distinct absorption in the UV/Vis area (380–420 nm) as shown in Figure 1 (below). It features a high extinction coefficient and excellent photo-permanence.

|

|

Figure 1. Absorbance and transmittance of UV absorbers. Solutions of 20 mg/l (absorbance, left) and 80 mg/l (transmittance, right) in chloroform. Method: Perkin Elmer UV/VIS/NIR spectrophotometer Lambda 650. HPT = high performance triazine; BZT = benzo-triazole; the numbers in the graph on the right-hand side indicate the wavelengths where 50% transmittance is observed.

|

|

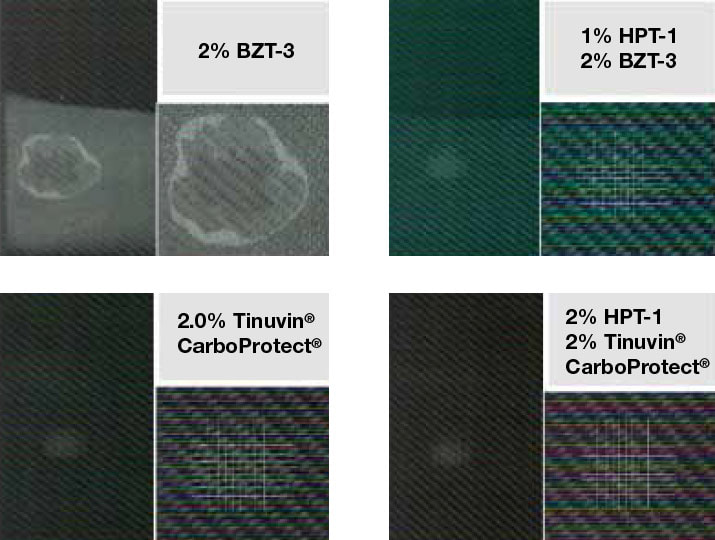

Weathering experiments illustrate the level of protection that Tinuvin CarboProtect provides to CFRM. After 2 years of natural weathering in Florida followed by 24 hours of humidity exposure, a CFRM protected by a solvent-based 2K PUR coating containing hindered amine light stabilizer (HALS) and a conventional benzotriazole (BZT-3) UV absorber fails a cross-hatch/tape adhesion test catastrophically as illustrated by the whitening and film delamination (Figure 2, top left). Adding a high performance triazine (HPT-1) in addition to BZT-3 improves the UV protection but does not eliminate deterioration as illustrated by strong whitening of the CFRM plaque (Figure 2, top right). The corresponding experiments with Tinuvin CarboProtect instead of the conventional UV absorber do not show any compromised adhesion of the coating nor whitening (Figure 2, bottom left and right), illustrating the superior performance of the advanced, red-shifted UV absorber.

|

Highlight carbon fiber weave in design elements in the cabin interior

The protection that Tinuvin CarboProtect provides to epoxy-based substrates is so effective that it enables pigment-free, transparent coatings with UV blocking strong enough for exterior applications. In addition, carbon fiber applications used in the cabin interior also require protection from UV radiation and can take advantage of Tinuvin CarboProtect. The option to use transparent coatings over CFRM allows for the carbon fiber weaves to be displayed and utilized as design elements in the cabin interior, for example in wall panels, decorative stripping, and laminating as well as furniture in business jets. For enhanced styling, low levels of pigments can be added to introduce color and metallic or pearlescent effects.

|

|

Figure 2. Whitening after humidity exposure. Weathering experiments (24 months Florida exposure) on epoxy-based CFRM, followed by 24 h humidity exposure and a cross-hatch/tape adhesion test. The CFRM were coated with solvent-based 2K PUR, containing 1% of HALS and the specified types and amounts of UV absorbers. HPT = high performance triazine; BZT = benzo-triazole.

|

Application guidelines

Tinuvin CarboProtect is a solid UV absorber, designed for solventborne coatings. While it was originally developed to stabilize carbon fiber reinforced epoxy, it is also suitable for coatings, laminates and plastic substrates as well as base coatings requiring strong protection both in the UV-A range and near visible spectral range.

Recommended applications are:

For outdoor applications, Tinuvin CarboProtect should be combined with a hindered amine light stabilizer such as Tinuvin 123 (for acid catalyzed systems) or Tinuvin 292 (for 2K PUR). HALS/UV absorber combinations are synergistic and impart superior coating protection against gloss reduction, cracking, blistering, delamination, and color change. In basecoat/ clearcoat systems, Tinuvin CarboProtect UV absorber should be added to the clear coat for maximum efficiency, and the HALS to both the base and the clear coats. For optimum spectral coverage, it can be combined with a triazine-based UV absorber such as Tinuvin 400 (in liquid paints) and Tinuvin 405 (in powder coatings).

|

|

Binder systems

Tinuvin CarboProtect is recommended in binder systems, such as:

|

Concentration

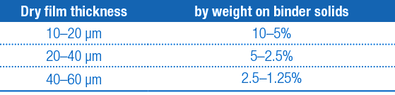

The concentration of Tinuvin CarboProtect depends on dry film thickness and desired degree of protection. The amount required for optimum performance should be determined in trials covering a concentration range.

|